Fixed-Length Pipe Cutting Machine

We operate two fixed-length automatic pipe cutting and chamfering machines dedicated to conveyor roller manufacturing. Each machine delivers a length accuracy of ±0.5 mm and a throughput of up to 800 pipes per shift.

This controlled cutting and chamfering process ensures:

Consistent and repeatable pipe lengths, critical for roller concentricity and balance

Burr-free, chamfered edges, eliminating sharp corners that can damage conveyor belts during operation

As a result, downstream assembly accuracy is improved and belt safety is inherently protected.

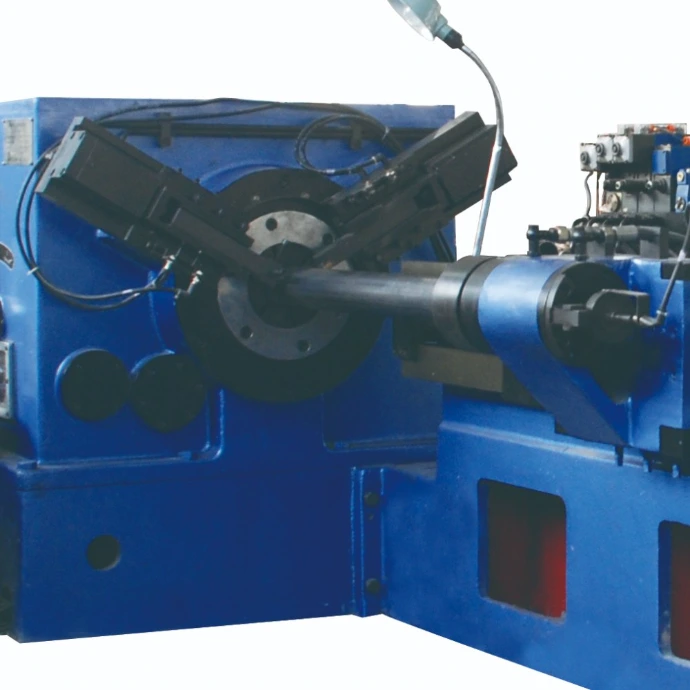

Double-Side Pipe Boring Machine

We operate two double-side pipe boring machines that machine both tube ends simultaneously, ensuring precise alignment between bearing seats.

This process is critical for:

Maintaining tube-to-bearing concentricity

Minimizing runout in the assembled roller

Improving bearing life and dynamic performance

Simultaneous end machining eliminates cumulative errors associated with single-side operations and directly enhances roller reliability in service.

Dual Head Welding Machines

We operate two in-house–designed double-side welding machines, developed using our extensive experience in building special purpose machines (SPMs).

These machines weld both ends simultaneously and in alignment, which:

Preserves roller concentricity during welding

Prevents distortion caused by heat imbalance

Maintains true bearing seat alignment

Directly contributes to longer conveyor roller service life

By controlling the welding process through purpose-built equipment rather than standard fixtures, we ensure consistent structural integrity and superior field performance of our rollers.

Powder Coating Machines

We operate an automated in-line powder coating system designed for conveyor roller production, ensuring uniform coating thickness and consistent surface finish.

This controlled process:

Provides superior corrosion resistance

Improves surface durability during handling and operation

Significantly increases the storage life of rollers

Ensures repeatable quality across high-volume production

As a result, rollers retain their protective finish and performance integrity even during extended storage and transportation.

Pressure Controlled Bearing & Seal Assembly

We operate a pressure-controlled bearing and seal assembly machine to ensure precise and repeatable installation of critical rotating components.

This controlled assembly process:

Prevents bearing preload and seal damage

Maintains correct axial and radial alignment

Eliminates installation-induced stresses

Directly improves bearing life and seal effectiveness

By controlling assembly forces rather than relying on manual methods, we ensure long-term reliability and extended service life of conveyor rollers.

TIR Checking Test Rig

We use a dedicated TIR (Total Indicator Runout) checking test rig to verify the rotational accuracy of every conveyor roller.

This inspection ensures:

Controlled radial and axial runout within specified limits

Verification of tube, shaft, and bearing seat concentricity

Early detection of welding distortion or assembly misalignment

Smooth rotation, reduced vibration, and lower bearing loads

TIR validation is a critical quality gate that directly impacts roller balance, bearing life, belt tracking, and overall conveyor reliability in mining, cement, and heavy-duty applications.

Rotational Resistance Testing

We conduct rotational resistance testing on conveyor rollers using a dedicated test rig to measure the starting and running torque of the assembled roller.

This test verifies:

Bearing and seal friction levels

Quality of bearing fitment and alignment

Effectiveness of sealing without excessive drag

Energy losses contributed by the roller

Low and consistent rotational resistance is essential for:

Reduced conveyor power consumption

Lower belt tension

Improved bearing life

Long-term system efficiency

This test ensures that rollers are not only dimensionally correct, but also mechanically efficient under real operating conditions.

Friction Factor Testing

WWe perform friction factor testing to quantify the rolling resistance contribution of conveyor rollers under controlled conditions. This test evaluates the combined effects of bearing quality, seal design, lubrication, alignment, and assembly accuracy.

The test verifies:

Coefficient of rolling resistance (f) at defined radial loads

Consistency across production batches

Impact of seal drag and bearing fit

Energy losses attributable to rollers

Engineering significance:

Lower friction factor directly translates to reduced conveyor power demand

Lower belt tension and drive loads

Improved bearing life and thermal stability

Measurable lifecycle cost reduction, especially on long overland and high-capacity conveyors

Friction factor testing bridges the gap between catalogue compliance and real system efficiency, ensuring rollers deliver predictable energy performance in the field, not just dimensional conformity.

Water Resistance Testing

We conduct water resistance testing to validate the effectiveness of roller sealing systems against water ingress under simulated site conditions.

This test evaluates:

Seal integrity under continuous water spray or immersion

Ingress protection at bearing and shaft interfaces

Seal performance under rotation

Resistance to wash-down and rain exposure

Engineering relevance:

Prevents bearing contamination and premature failure

Ensures reliable operation in wet, humid, and monsoon-prone environments

Protects lubrication integrity

Extends roller service life in mining, cement, and port applications

Water resistance testing ensures that sealing performance is proven under realistic exposure conditions, not assumed from seal design alone—directly supporting long-term conveyor reliability and reduced maintenance risk.

Dust Resistance Testing

We perform dust resistance testing to assess the ability of conveyor roller sealing systems to prevent fine particulate ingress under simulated operating conditions.

This test evaluates:

Seal effectiveness against fine and abrasive dust

Ingress protection at bearing and shaft interfaces

Seal performance during continuous rotation

Resistance to contamination in high-dust environments

Engineering relevance:

Prevents abrasive wear of bearings and races

Maintains lubrication cleanliness

Reduces premature bearing failure

Ensures reliable operation in mining, cement, power, and aggregate handling applications

Dust resistance testing confirms that sealing systems are validated for real plant conditions—where airborne dust, not load alone, is often the primary cause of conveyor roller failure.