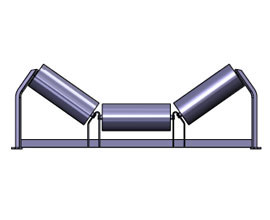

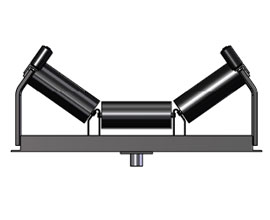

CEMA C Idler – Imperial Specification (US Customary Units)

CEMA C Idlers are designed for medium to heavy-duty belt conveyor applications operating under continuous loads. Manufactured as per Conveyor Equipment Manufacturers Association (CEMA) standards, they are widely specified by EPC contractors, OEMs, and mine operators across North America and global export projects.

What Defines a CEMA C Idler (Imperial Context)

CEMA C represents a higher load rating and structural robustness than CEMA B, suitable for conveyors with:

Higher belt tensions

Larger lump sizes

Longer center distances

24/7 operating cycles

It is typically the baseline duty class for mining and heavy industrial conveyors.

Key Engineering Features

Heavy-wall steel roller shells for impact and fatigue resistance

Precision-turned steel shafts to control deflection under load

Premium deep-groove ball bearings (L10 life optimized)

Multi-stage labyrinth seals to block dust, water, and fines

Low rolling resistance for reduced conveyor power demand

Dynamic balancing for smooth operation at higher belt speeds

Available Idler Types

Troughing Idlers – 20°, 35°, 45° trough angles

Return Idlers – Flat return or V-return

Impact Idlers – Rubber disc or HDPE disc (loading zones)

Training Idlers – Self-aligning types

Special / Garland Idlers – On request

Typical Imperial Technical Range

| Parameter | CEMA C (Imperial) |

|---|

| Belt Width | 18 in to 72 in |

| Roller Diameter | 5 in, 6 in |

| Shell Thickness | 0.157 in – 0.197 in |

| Shaft Diameter | 1 in – 1.25 in |

| Belt Speed | Up to ~1000 FPM |

| Duty Class | Medium to Heavy |

(Final sizing depends on belt tension, material density, idler spacing, and impact loading.)

Industries & Applications

Surface & underground mining conveyors

Cement plants (raw material & clinker handling)

Aggregate & crushing systems

Coal handling systems in power plants

Steel mills & bulk terminals

Why Specify CEMA C Idlers

Longer bearing and roller life vs light-duty idlers

Lower total cost of ownership (TCO)

Reduced belt wear and misalignment issues

Globally accepted standard for EPC and OEM projects

Engineering Buyer Note

For conveyors operating >20 hours/day, belt widths ≥36 in, or material bulk density above 80 lb/ft³, CEMA C idlers should be treated as the minimum safe design class. Using lower-class idlers often results in early bearing failure, higher power consumption, and unplanned shutdowns.